Pumps in the chemical industry

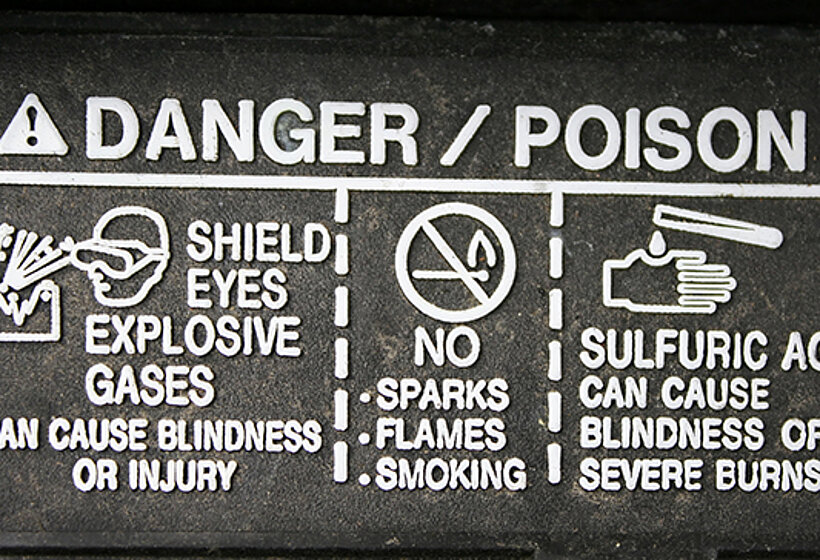

The chemical industry has perhaps the greatest demand for pumps that both perform and provide protection to employees and the surrounding work environment. A chemical producer will have to handle aggressive acids which are not only toxic, but also highly flammable and explosive. Alongside the handling of dangerous fluids will be the thermal control of the process as well as the treatment of effluent through chemical dosing or even nanofiltration.

At Verder, we have substantial experience in pumping chemicals. For these applications we offer peristaltic, diaphragm, and centrifugal pump principles. Thanks to our extended product range and the variety of choices of wetted materials, we can offer you the right pump solution whether for dosing, transfer or liquid circulation.

Looking for a pump solution?

If you need help deciding which pump is best for your application, please feel free to contact our pump experts