PHP2

The Packo 3A certified pharmaceutical process pumps of the PHP2 series are used in the most demanding sterile applications in the pharmaceutical, biotech and semi-conductor industry. These perfectly cleanable process pumps are the ideal solution for pure water circulation loops, cleaning applications, etc. Typical liquids are pure water, WFI, CIP, syrups, etc.

-

Properties

Property Max. flow 110 m3/h Differential head 110 m wc Max. Inlet pressure 13 bar Viscosity 1000 cP Max. temperature 140 °C Impeller type Open Max. free passage 22 mm Max. drive power 45 kW Speed 3000 / 3600 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L for casing and backplate, 1.4435 for the impellers, duplex 1.4462 for metallic parts of the seal and impeller screw Available materials O-ring EPDM, FKM, FEP-FKM, FFKM, Silicone Mechanical seal configuration Single, quench, double Connections Sterile connections Surface finish Pharmaceutical quality, roughness value < 0,4 µm for wetted parts, electropolished and fully certified. Certificates 3A. 1935/2004 EC. FDA. USP. ATEX. EAC -

Description

The Packo 3A certified pharmaceutical process pumps of the PHP2 series are used in the most demanding sterile applications in the pharmaceutical, biotech and semi-conductor industry. These perfectly cleanable process pumps are the ideal solution for pure water circulation loops, cleaning applications, etc. Typical liquids are pure water, WFI, CIP, syrups, etc.

Pump series PHP2

The Packo 3A certified pharmaceutical process pumps of the PHP2 series are used for the most demanding sterile applications in the pharmaceutical, biotech and semi-conductor industry. These perfectly cleanable pumps have stainless steel 316L pump casings constructed in thick cold rolled plate, 100% non porous and extremely smooth.

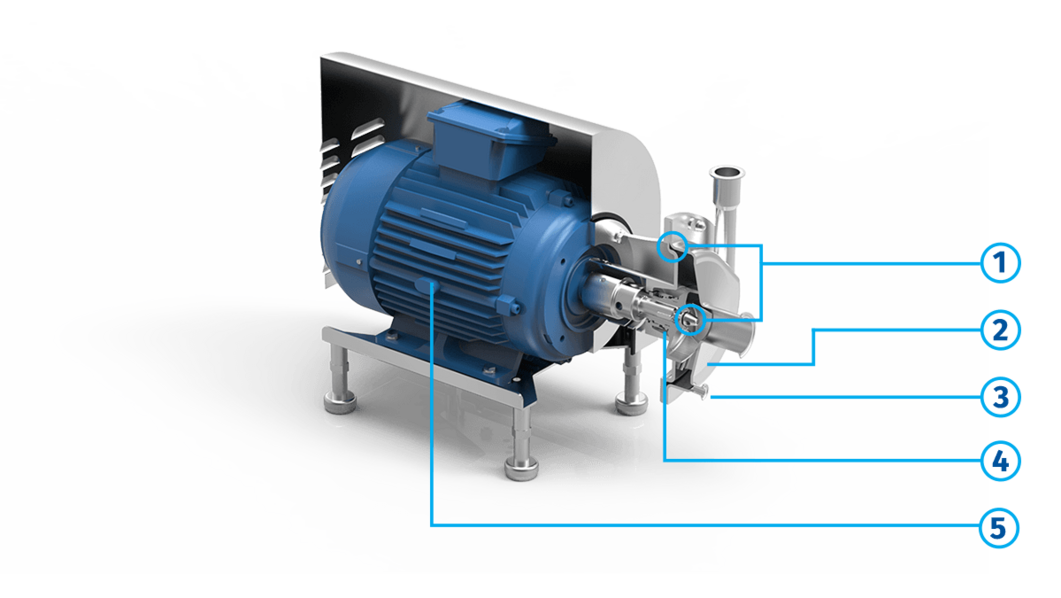

The pumps have fully machined open impellers constructed in 1.4435 material. Thanks to its crevice-free design and electropolishing as a final surface treatment, the PHP2 pump series are perfectly cleanable, resulting in a reliable component into your production process.

- Electropolished, easy to clean construction, no bacteria traps and no small clearances in order to clean the area around the O-ring

- Pressed stainless steel pump casing in 2B, extremely smooth

- Large seal cavity to clean mechanical seal properly

- Fully drainable

- Monobloc execution with std. IEC motors

Application areas

These perfectly cleanable process pumps are the ideal solution for pure water circulation loops, cleaning applications, etc.

Typical liquids are pure water, WFI, CIP, syrups, etc.

Your benefits

- High pump efficiency lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: perfectly cleanable

- Easy & robust construction and easy maintenance: Less downtime

- Standard components

- 2 mechanical seal diameters for entire range

- Fully certified (roughness value, FDA, USP, 3.1 for wetted parts, certificate of conformity, etc.)

- Suitable for SIP

- Parts in contact < 0,4 μm

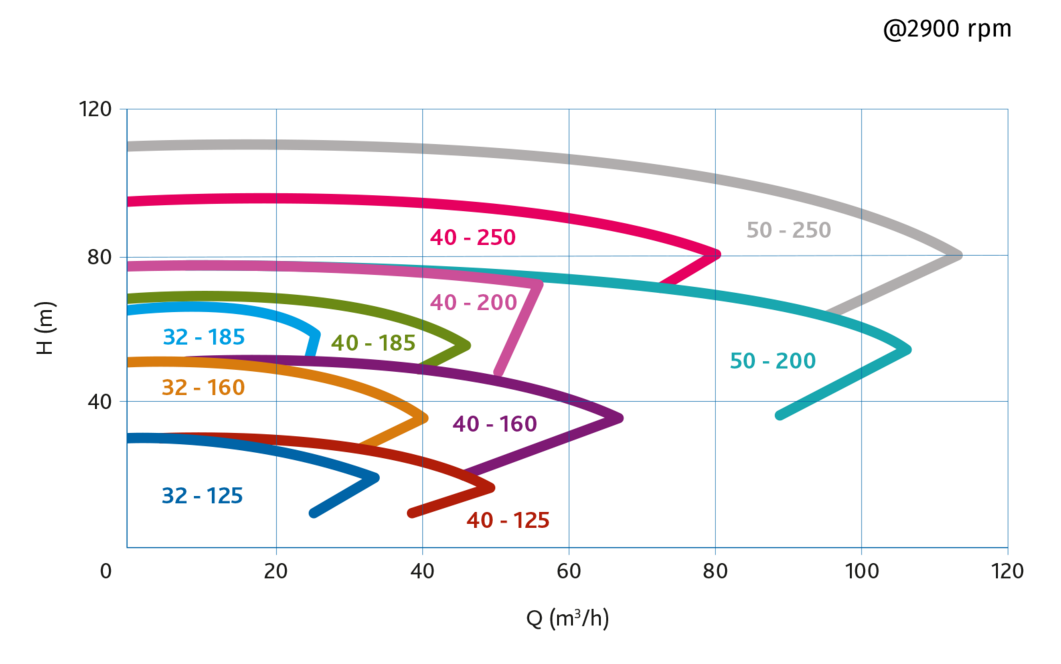

Performance Curves

Assembly and disassembly videos

For all different configurations of this pump series you can find an assembly/disassembly video here. These videos show easy to follow steps to assemble the pumps and replace the seals.

Assembly video - configuration with sterile seal

Disassembly video - replacement of sterile seal

Assembly video - bellows seal configuration

Assembly video - configuration with quench and bellows seal