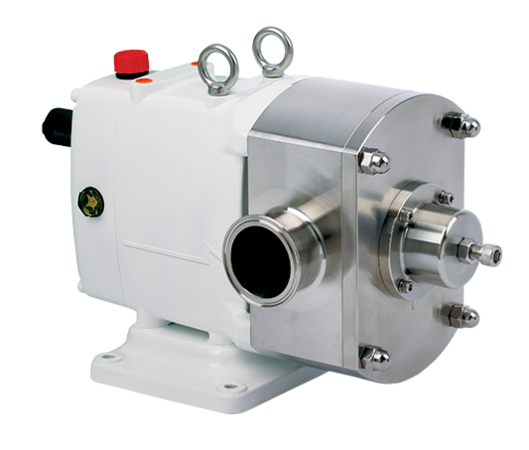

ZL

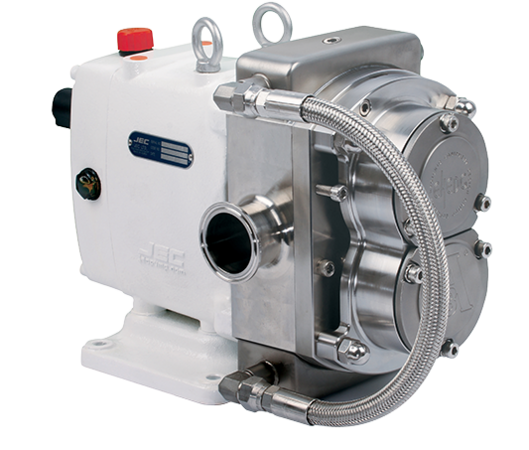

The Packo ZL series of rotary lobe pumps is designed for a broad application spectrum covering dairies, foods, beverages, pharmaceuticals, cosmetics, bakeries, detergents, liquors and chemical industries. They are designed specifically for conveying fluids in the low to high viscosity range with gentle product handling. With high grade 0.6㎛ Ra surface finish, unique seal and casing design, ZL series are suitable for Cleaning In Place (CIP) and offer exceptional levels of hygiene. The wetted parts are made of SS 316L. Our broad range of seal options such as mechanical seal, O-ring seal and Lip seal provides optimal solution for your need and application. Optimal CIP is realized with O-ring position which prevent dead corners between front cover and casing.

-

Properties

Property Max. flow 440 GPM Max. (discharge) pressure 290 PSI Viscosity 1000000 cPs Max. temperature 302 °F Certificates 1935/2004EC. FDA. USP. ATEX. EAC Port 25-125 inch Speed 1000 rpm Materials wetted parts Stainless Steel 316L -

Description

The Packo ZL series of rotary lobe pumps is designed for a broad application spectrum covering dairies, foods, beverages, pharmaceuticals, cosmetics, bakeries, detergents, liquors and chemical industries. They are designed specifically for conveying fluids in the low to high viscosity range with gentle product handling. With high grade 0.6㎛ Ra surface finish, unique seal and casing design, ZL series are suitable for Cleaning In Place (CIP) and offer exceptional levels of hygiene. The wetted parts are made of SS 316L. Our broad range of seal options such as mechanical seal, O-ring seal and Lip seal provides optimal solution for your need and application. Optimal CIP is realized with O-ring position which prevent dead corners between front cover and casing.

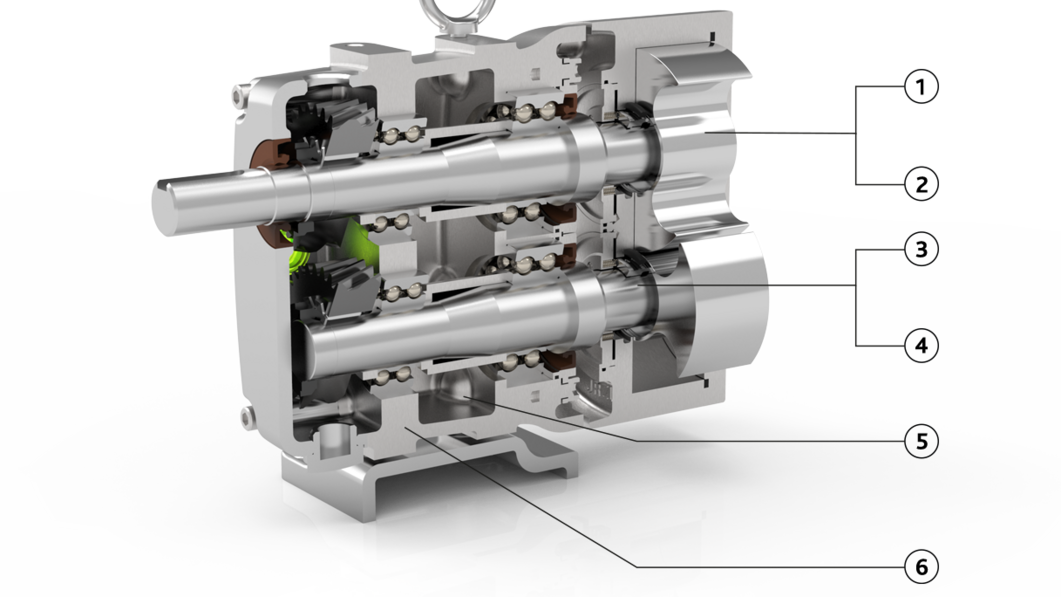

- Available with various rotor geometries (Bi-Wing, Tri-Lobe, Heli-Lobe, Multi-Lobe, Single Wing, Bi-Lobe): the optimal solution is available for every application.

- Rotors can be changed without timing spindles, or opening the gearbox for adjustments.

- Available with various sealing arrangements: single, flushed, double, O-ring seal, triple lip seal, etc. which are interchangeable.

- Wetted seal parts can be replaced without disassembling the rotor case: pump does not need to be mounted out of the installation to change seals.

- Food grade oil-filled gearbox increases bearing lifetime and requires minimal service effort. Ball bearings generate very low heat, helical and grinded gears guarantee smooth operation.

- Investment cast stainless steel gearbox available

Application areas

The Packo pumps of the ZL series are designed for a wide range of hygienic applications in dairies, breweries, the pharma and cosmetics industry and bakeries, as well as for pumping liqueurs, detergents, shampoos, gels, etc. They are the ideal solution for gentle pumping of low to high viscous liquids.

Your benefits

-

Cleaner

- Certified to EC1935/2004, EHEDG and 3A versions available

- Wetted surfaces with Ra < 0.6 µm

- Wetted parts in SS316L - Improved CIP performance

- Optimized design to eliminate dead spaces, O-ring grooves without dead corners

- Wetted parts of mechanical seals directly in the product stream -

Shorter downtimes / higher flexibility

- Faster maintenance

- Pump can stay in piping during replacing seals thanks to front loaded seals

- No need to open gearbox for adjusting axial clearances between rotors and casing

- Rotors can be changed without timing - Universal mounting

- Top or bottom shaft can be switched without gearbox disassembly

- Pumps can be mounted with both horizontal and vertical port connections - Heating jackets for casing and front cover, pressure relieve valve, by-pass valve and many more options available