55/320

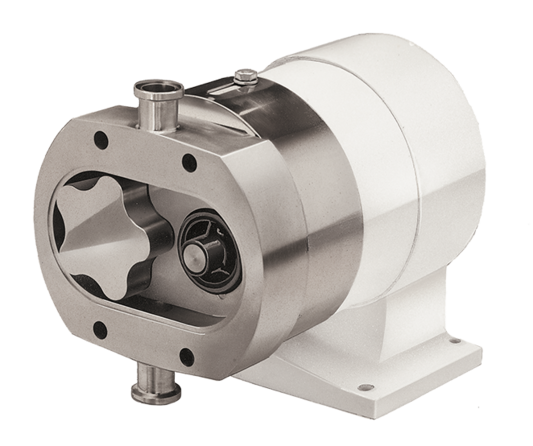

Serija Packo 55 predstavlja vrhunski razvoj rotirajućih volumetrijskih pumpi za farmaceutsku i prehrambenu industriju. Pumpe su dizajnirane da ponude najviše standarde za CIP (čišćenje -u-mestu) i SIP (sterilizacija-u-mestu) i aseptični rad (otpornost protiv prodiranja npr, mikroorganizama preko zglobova). Najglatke površine u kombinaciji sa dizajnom bez mrtvih prostora, upotpunjene spoljnom fiksacijom rotora, čine seriju 55 savršenim rešenjem za sve oblasti u kojima je potrebna najveća bezbednost proizvoda i mogućnost čišćenja.

-

Svojstva

Tehničke karakteristike Port Size Inlet/ Outlet Standard 3/4" (19 mm) Port Size Inlet/ Outlet Standard 3/4" (19 mm) Displacement US Gallons (Litres) 0.77 Gallons (2.9 litre) @ 100 revs Displacement US Gallons (Litres) 0.77 Gallons (2.9 litre) @ 100 revs Flow Rate US Gallons (litres) 11.6 GPM (44 LPM) Flow Rate US Gallons (litres) 11.6 GPM (44 LPM) Operating Pressure 290 psi (20 bar) Operating Pressure 290 psi (20 bar) Brzina obrtanja 1500 max (rpm) Brzina obrtanja 1500 max (rpm) Operating Temperature -22 to 284°F (-30 to 140°C) Operating Temperature -22 to 284°F (-30 to 140°C) Dimensions (H X W X D) 264 x 145 x 168 (mm) Dimensions (H X W X D) 264 x 145 x 168 (mm) Težina 19 (kg) 42 (lb) Težina 19 (kg) 42 (lb) Body Materials 316L Stainless Steel Body Materials 316L Stainless Steel Rotor 316L Stainless Steel Rotor 316L Stainless Steel Port Type All US and European standards Port Type All US and European standards Seal Front-loaded single mechanical face-type seals of hygienic design. Materials include carbon and silicon carbide. Low-pressure flush seals use the same single mechanical seal with an additional housing. Double mechanical seals use all the components from s Seal Front-loaded single mechanical face-type seals of hygienic design. Materials include carbon and silicon carbide. Low-pressure flush seals use the same single mechanical seal with an additional housing. Double mechanical seals use all the components from s Bearings High specification taper roller bearings Bearings High specification taper roller bearings Approvals EHEDG CIP, SIP and Bacterial tightness protocols; 3A sanitary standards 18-03 and 02-11; uses materials that meet FDA title 21, section 177.1550 Approvals EHEDG CIP, SIP and Bacterial tightness protocols; 3A sanitary standards 18-03 and 02-11; uses materials that meet FDA title 21, section 177.1550 -

Opis

Serija Packo 55 predstavlja vrhunski razvoj rotirajućih volumetrijskih pumpi za farmaceutsku i prehrambenu industriju. Pumpe su dizajnirane da ponude najviše standarde za CIP (čišćenje -u-mestu) i SIP (sterilizacija-u-mestu) i aseptični rad (otpornost protiv prodiranja npr, mikroorganizama preko zglobova). Najglatke površine u kombinaciji sa dizajnom bez mrtvih prostora, upotpunjene spoljnom fiksacijom rotora, čine seriju 55 savršenim rešenjem za sve oblasti u kojima je potrebna najveća bezbednost proizvoda i mogućnost čišćenja. -

Preuzimanja