Verderflex Ds500

Scoprite la precisione, l'affidabilità e la flessibilità della pompa tubolare Ds500 unendovi alla crescente comunità di clienti Verderflex della Ds500 abilitati...

| Portata massima | 30 l/h |

| Massima pressione di scarico | 7 bar |

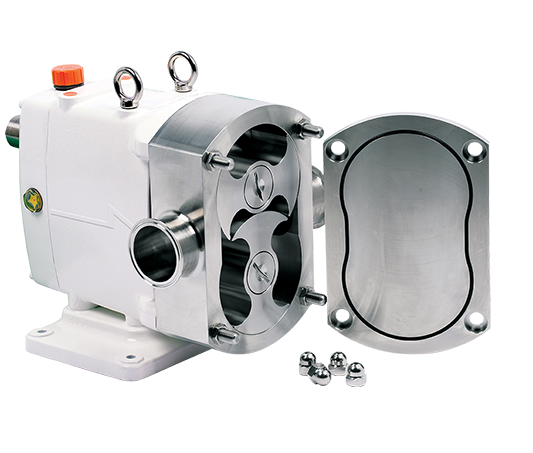

La serie ZL comprende pompe progettate per un'ampia gamma di applicazioni che coprono prodotti lattiero-caseari, alimenti, bevande, prodotti farmaceutici, cosmetici, panetterie, detersivi, liquori e industrie chimiche. Le pompe sono progettate per il trasporto delicato di fluidi sia viscosi che non.

La pompa a lobi rotativi Packo è, nel suo campo, un'eccellenza. La pompa può essere dotata di una varietà di caratteristiche e rotori per adattarsi a quasi tutte le attività di pompaggio igieniche. Possono essere effettuate personalizzazioni per il raggiungimento di prestazioni ottimali.

|

|

|

|

|

|

|

|

|

|

|

|

|

ZL105-002-20 |

ZL110-005-20 |

ZL115-012-12 |

ZL120-021-08 |

ZL220-040-12 |

ZL225-062-08 |

ZL330-102-12 |

ZL340-144-08 |

ZL440-227-12 |

ZL450-334-08 |

ZL560-1200-02 |

|

| Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | Visualizza la pompa | |

| Portata massima |

20 l/min

|

50 l/min

|

96 l/min

|

168 l/min

|

287 l/min

|

434 l/min

|

612 l/min

|

864 l/min

|

1135 l/min

|

1670 l/min

|

3600 l/min

|

| Massima pressione di scarico |

20 bar

|

20 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

4 bar

|

| Port |

25 mm

|

25 mm

|

38 mm

|

50 mm

|

50 mm

|

63 mm

|

76 mm

|

100 mm

|

100 mm

|

125 mm

|

150 mm

|

| Velocità |

1000 rpm

|

1000 rpm

|

800 rpm

|

800 rpm

|

700 rpm

|

700 rpm

|

600 rpm

|

600 rpm

|

500 rpm

|

500 rpm

|

300 rpm

|

| Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica | Scarica la scheda tecnica |

I nostri esperti ti aiuteranno a scegliere la pompa giusta per il tuo processo!

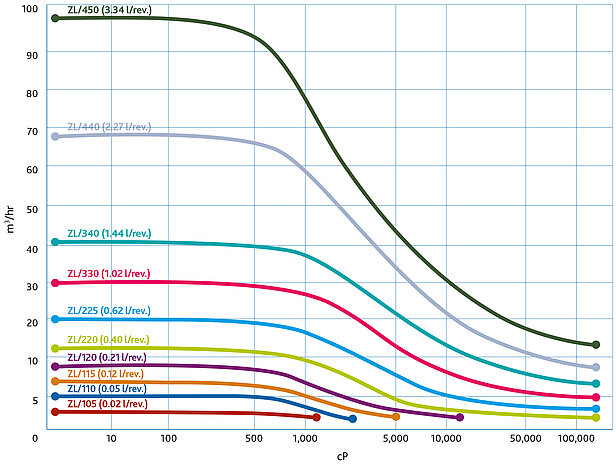

| Tipo | Litri / giro | Pressione massima | Connessioni (mm) | Giri massimi |

|

ZL/105 |

0.02 |

20 |

25 |

1.000 |

|

ZL/110 |

0.05 |

20 |

25 |

1.000 |

|

ZL/115 |

0.12 |

12 |

40 |

800 |

|

ZL/120 |

0.21 |

8 |

50 |

800 |

|

ZL/220 |

0.4 |

12 |

50 |

700 |

|

ZL/225 |

0.62 |

8 |

65 |

700 |

|

ZL/330 |

1.02 |

12 |

80 |

600 |

|

ZL/340 |

1.44 |

8 |

100 |

600 |

|

ZL/440 |

2.27 |

12 |

100 |

500 |

|

ZL/450 |

3.34 |

8 |

125 |

500 |

Scoprite la precisione, l'affidabilità e la flessibilità della pompa tubolare Ds500 unendovi alla crescente comunità di clienti Verderflex della Ds500 abilitati...

| Portata massima | 30 l/h |

| Massima pressione di scarico | 7 bar |

Le pompe Verderair PURE sono progettate per applicazioni gravose, per gestire prodotti chimici aggressivi come acidi e solventi o in condizioni di processo difficili,...

| Portata massima | 660 l/min |

| Massima pressione di scarico | 7 bar |

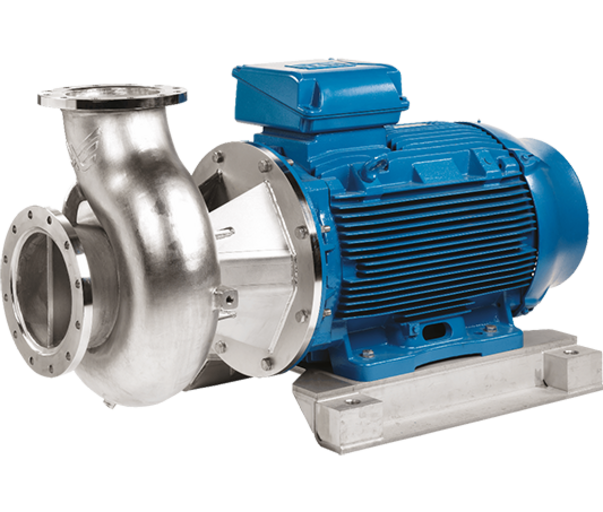

La gamma di pompe industriali Packo Standard ha un'efficienza molto elevata e un NPSH molto basso. Tutte le pompe di questa serie sono robuste e di facile...

| Portata massima | 1800 m3/h |

| Massima altezza di aspirazione | 160 m wC |