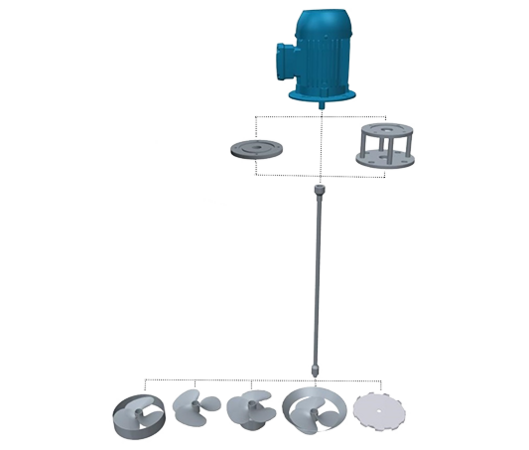

VSM

This type of agitator uses a special electric motor with a hollow motor shaft. The robust mixer shaft is fi xed with both a conical and a cylindrical fi t. Due to the hollow shaft construction the bearings are over dimensioned. A robust and stable design; a perfect construction for heavy duty applications.

-

Properties

Property Options Sealing lantern with a mechanical seal, lip seal or stuffi ng box, chemical resistant coating. Additional Fixed or portable stands can be constructed to meet customers specifi cations and requirements. Shaft speeds Between 750 and 1800 rpm Shaft length Up to 2500 mm Mixing elements PS (foldable) - L - PSL - Z - RB -

Description

This type of agitator uses a special electric motor with a hollow motor shaft. The robust mixer shaft is fi xed with both a conical and a cylindrical fi t. Due to the hollow shaft construction the bearings are over dimensioned. A robust and stable design; a perfect construction for heavy duty applications. -

Downloads