Pumps for Unloading Applications

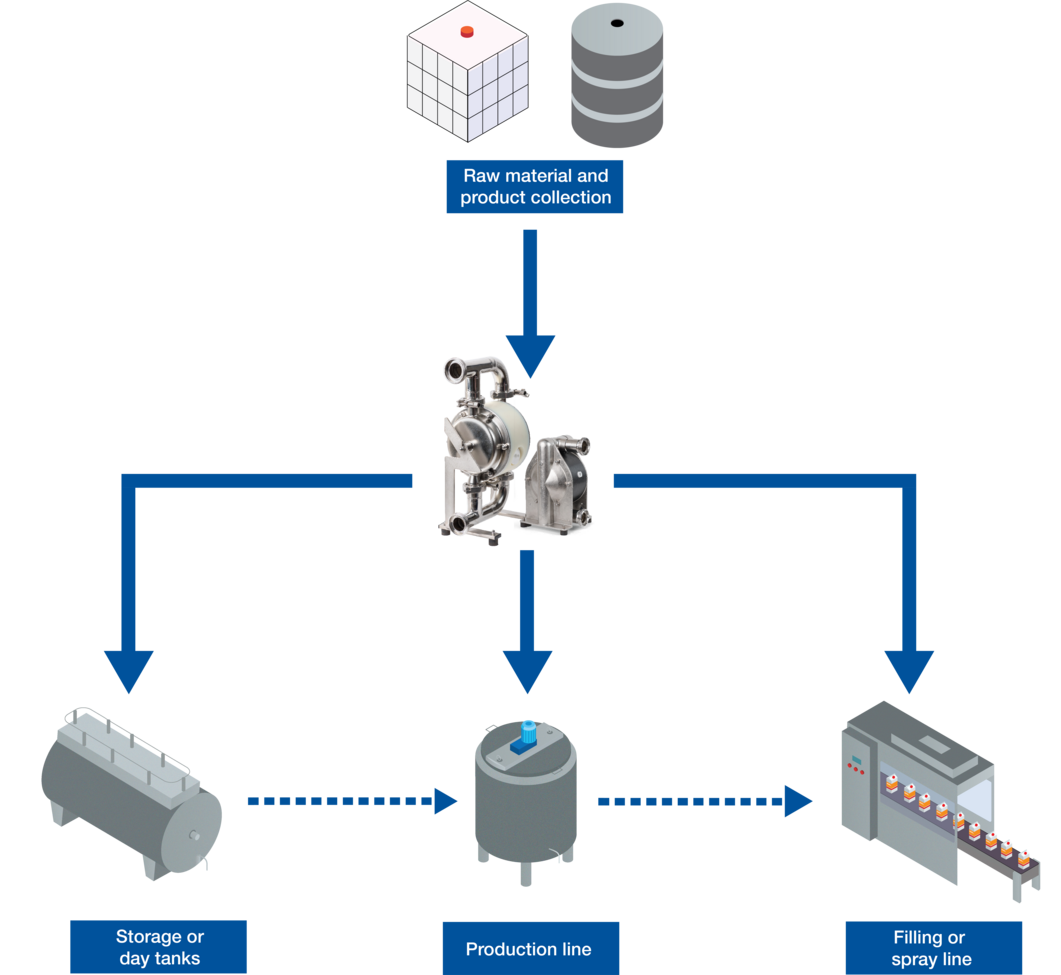

Unloading drums, tanks, IBCs, or trucks is a crucial step for any company to initiate their production process. Typical applications include transferring ingredients, additives, or finished products from drums, IBCs, tanks, or trucks into storage vessels, production lines, or filling machines. Typical industries are Food & Beverage, Dairy Processing, Breweries & Distilleries, Pharmaceutical, Cosmetics and OEM. Hygienic Diaphragm Pumps are the perfect fit.

The Unloading Process

Hygienic diaphragm pumps are specifically designed for unloading applications in industries where cleanliness and product integrity are paramount, such as food and beverage, pharmaceuticals, and cosmetics. These pumps are constructed with smooth, easy-to-clean surfaces and materials that meet strict sanitary standards, minimizing the risk of contamination during unloading from drums, IBCs, or tanks.

Key considerations when using hygienic diaphragm pumps for unloading include selecting pumps with appropriate certifications (such as FDA or EC-1935/2004), ensuring all wetted parts are made from food-grade materials, and implementing clean-in-place (CIP) or sterilize-in-place (SIP) procedures. Other important factors to be considered such as fluid compatibility, flow rate, suction lift, dry running, and the presence of solids in the fluid. It is also important to maintain gentle product handling to preserve product quality, avoid shear-sensitive damage, and prevent cross-contamination. Regular inspection and maintenance of seals, diaphragms, and connections further ensure reliable and safe operation. Proper pump selection and adherence to hygiene protocols are critical to achieving efficient, contamination-free unloading in sensitive production environments.

Interested in a Pump for Unloading Applications?

One of our experts is here to help you.

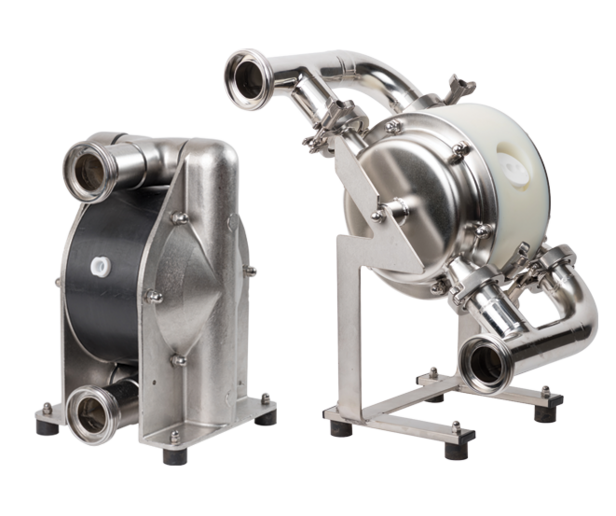

Why the Verderair HC-PURE?

Efficient, hygienic unloading starts with the right pump. Why is the Verderair HC‑PURE the ideal choice for your operation?

- Hygienic design: Smooth, eletropolished surfaces with FDA & EC-1935/2004‑approved materials prevent contamination and simplify cleaning (CIP/SIP).

- Gentle product handling: Low shear pumping preserves texture and quality of sensitive fluids.

- Versatile performance: Handles a wide range of viscosities, solids, and temperatures with reliable, consistent flow.