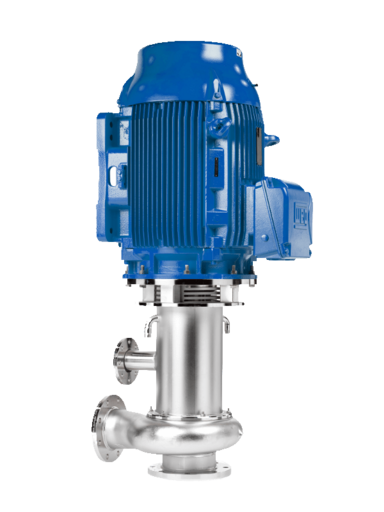

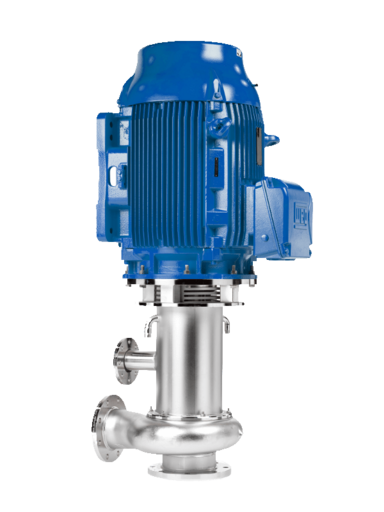

IMO

| Max. flow | 1000 m3/h |

| Differential head | 60 m wc |

In the food industry, reliability, safety, and hygiene in fryer systems are of utmost importance. Fryer applications operate under extreme temperatures and must uphold the highest standards to ensure both product quality and operational efficiency. Hot oil in combination with food particles can quickly compromise conventional pumps, leading to leaks, breakdowns, and costly maintenance.

We tackle these challenges at the source by eliminating the main point of failure: the mechanical seal. Our innovative, sealless cantilever Packo IMO pump is designed specifically for demanding fryer applications, where temperatures can reach up to 200°C (392°F). This pump is perfectly cleanable, completely leak-free, and engineered to withstand the aggressive conditions found in industrial fryers.

Whether you are processing potato products such as fries and chips, or frying chicken fingers, fish sticks, donuts, and more, our hygienic cantilever pump delivers a reliable, low-maintenance, and long-lasting solution. By choosing Verder liquids, you ensure maximum uptime, optimum hygiene, and peace of mind for your production line

| Max. flow | 1000 m3/h |

| Differential head | 60 m wc |

The Packo IMO sealless cantilever operation makes it especially well-suited for frying oil applications in the food industry. By eliminating shaft seals, the pump prevents oil leaks and contamination, ensuring the highest standards of hygiene and product safety.

You can see it in operation in the following video: