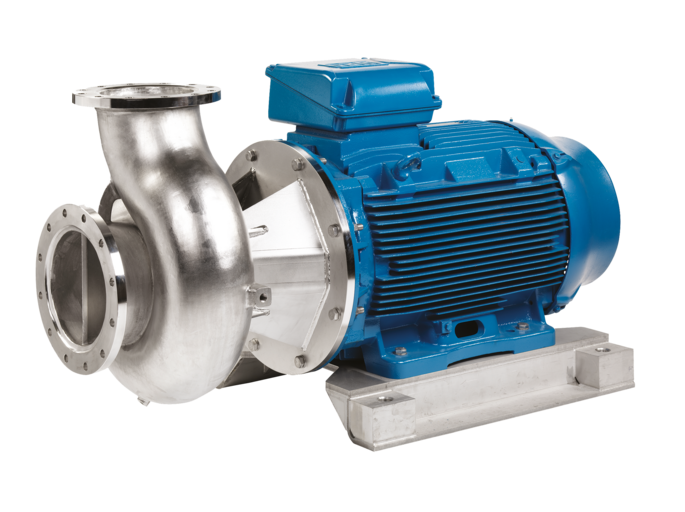

General Industrial Series

The Packo general industrial pump series excel with their high efficiency and low NPSH. The close-coupled modular construction of these pumps uses standardized...

| Max. flow | 1800 m3/h |

| Differential head | 220 m wC |

Verder Liquids can offer you the best pump solution in every step of the proces due to the very wide portfolio. For this specific case, a range of Packo pumps was selected for the application.

We have solutions for problems as:

Whether it is about pumps, advice, service, maintenance or parts: Verder Liquids is your partner!

Our experts can help you find the right pump for your process!

Milk Truck Collection

Milk transfer to storage

Milk transfer to Pasteurization

Milk transfer to centrifuge

Buttermilk transfer

Packo RMO series

We always start from your process and associated Total Cost of Ownership (TCO). Based on this calculation we choose for a centrifugal or lobe/ twin screw.

CIP

CIP+: Packo FP / ICP / MFP serie

CIP-: Packo CRP / MSCP serie

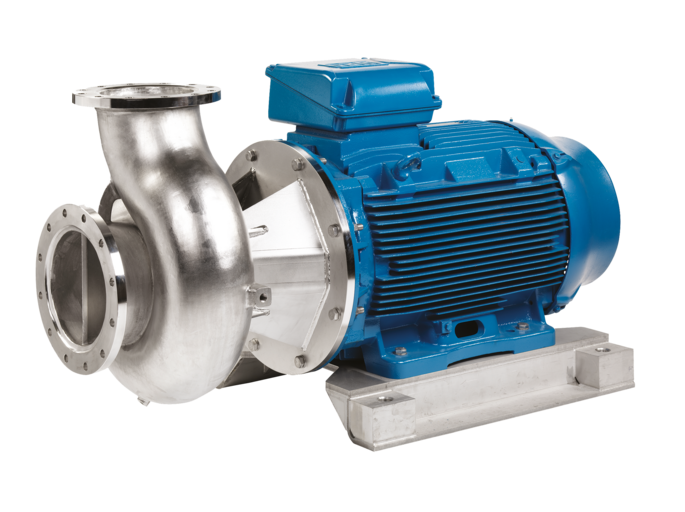

The Packo general industrial pump series excel with their high efficiency and low NPSH. The close-coupled modular construction of these pumps uses standardized...

| Max. flow | 1800 m3/h |

| Differential head | 220 m wC |

The Packo sanitary pump series are designed for use in the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. They are the ideal solution for filtration applications, pasteurisation, evaporating systems, yeast propagation and for CIP cleaning systems as well.

| Max. flow | 1800 m3/h |

| Differential head | 220 m wC |

Cream to cheese Pasteurization

Cream to butter installation

Butter to form and filler

EC 1935/2004, FDA, 3A, EHEDG, ATEX

Each series of the Packo rotary lobe pumps is, in its field, a state-of-the-art. The pumps can be fitted with a variety of features and rotors to adapt to almost all hygienic pumping tasks. The pumps can be customized for an optimum function or performance to your process.

| Max. flow | 1670 l/min |

| Max. discharge pressure | 20 bar |

All advantages of rotary lobe and centrifugal pumps are combined in the Packo twin screw series. This two-in-one pump is excellent for pumping high viscous liquids & pastes but also the thin-liquid cleaning fluids that are used for CIP cleaning. Pulsation free for gentle operation.

| Max. flow | 1660 l/min |

| Max. discharge pressure | 12 bar |