10 Essentials when Selecting a Double Diaphragm Pump

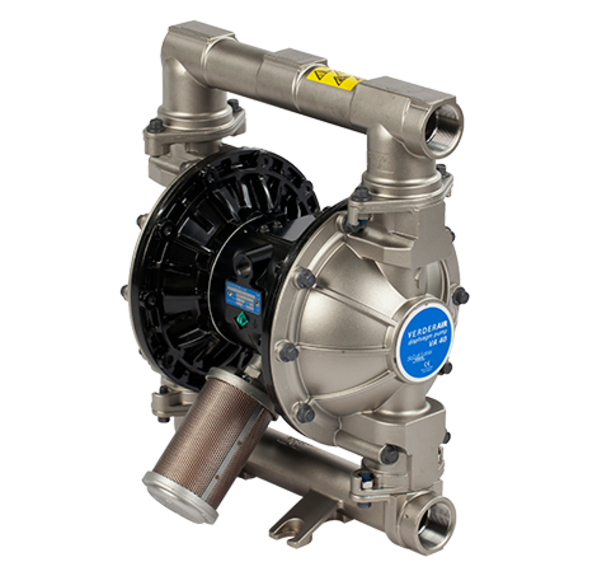

Diaphragm pumps come in different configurations, including metallic, non-metallic, with certain certifications and specifications. Every detail on your diaphragm pump will dictate how well it will perform in your application. This whitepaper discusses 10 essentials to consider when choosing a diaphragm pump, including:

- Fluid compatibility and the effect this has on making the right choice

- The influence of viscosity

- How to find the working point of a performance curve.

Fluid Compatibility

The selection of the best diaphragm pump begins with a determination of the fluid parameters you are pumping. Important factors to consider include the fluid’s chemical corrosiveness, temperature, and specific gravity (SG).

These diaphragm pumps are capable of handling the following fluids and many more:

- Chemicals

- Slurries

- Syrups

- Gels

- Creams

Process parameters

The process parameters are also very important. What is the flow rate and the temperature of the medium in the process? Does the process line have a positive or negative suction head, and what are the conditions at the discharge and suction sides?

In cases of cavitation, the impellers of industrial pumps often develop holes, and the vibration caused can lead to the destruction of bearings, mechanical seals, shaft connections, or even the breaking of impeller screws.

The whitepaper discusses checkpoints for process parameters to ensure everything runs optimally.