IMO

The Packo submersible cantilever pump series IMO are suitable for handling liquids with a temperature up to 200°C. They are especially constructed to handle liquids that are difficult to seal such as paints, varnishes, galvanic coatings, hot frying oil, etc. Particularly suitable for pumping liquids that are difficult to seal such as hot frying oil up to 200° C. They are also used for pumping waste water from industrial waste such as CIP, acids, condensate, etc.

-

Properties

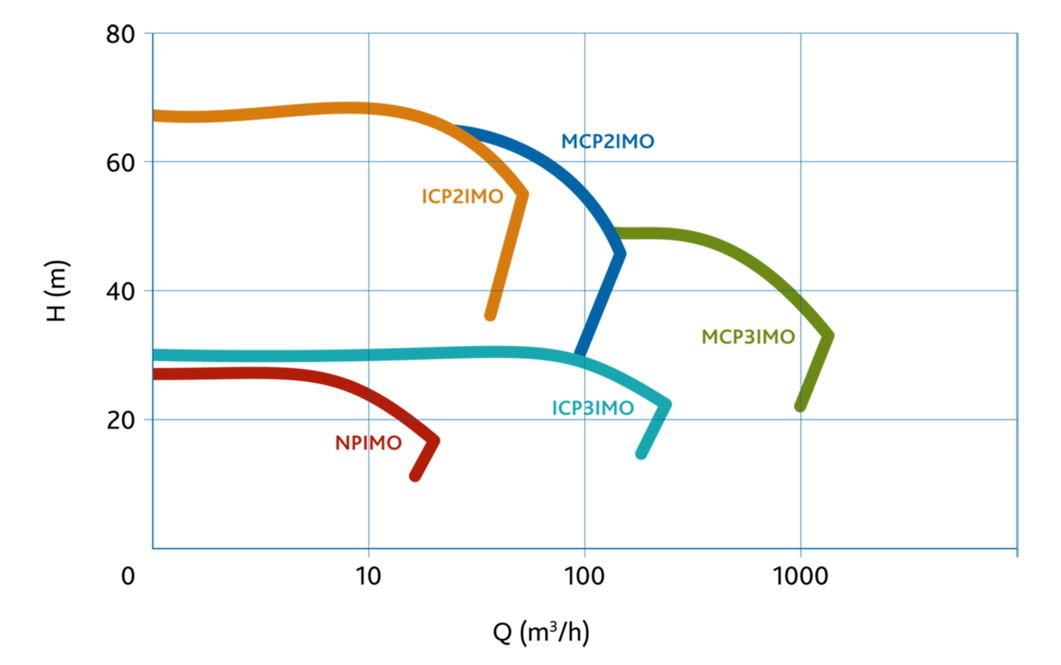

Property Max. flow 1000 m3/h Differential head 60 m wc Max. Inlet pressure Atmospheric Viscosity 1000 cP Max. temperature 200 °C Impeller type Open. semi-open or closed Max. free passage 45 mm Max. drive power 250 kW Speed 3000 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L or similar Mechanical seal configuration No seal - cantilever Available O-ring materials FKM - EPDM - Special Connections Industrial or hygienic Surface finish Industrial finish: welds are not hand polished. final surface treatment: electropolished Certificates 1935/2004 EC. MEI. EAC -

Description

The Packo submersible cantilever pump series IMO are suitable for handling liquids with a temperature up to 200°C. They are especially constructed to handle liquids that are difficult to seal such as paints, varnishes, galvanic coatings, hot frying oil, etc. Particularly suitable for pumping liquids that are difficult to seal such as hot frying oil up to 200° C. They are also used for pumping waste water from industrial waste such as CIP, acids, condensate, etc.

Pump series IMO

The Packo submersible cantilever pump series IMO are suitable for handling liquids with a temperature up to 200°C. They are especially constructed to handle liquids that are difficult to seal such as paints, varnishes, galvanic coatings, hot frying oil, etc.

The pumps have a working length of 500 mm. (= maximum level of the liquid above the suction of the pump)

The MCP3IMO pumps are also available on pedestal with a working length of 900 mm.

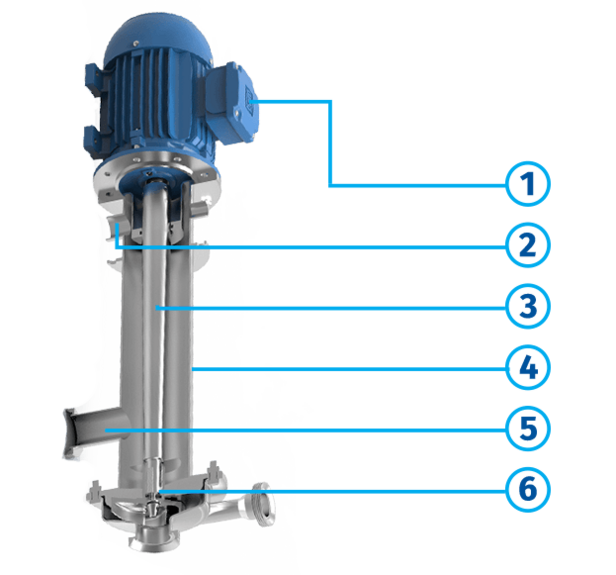

- Use of standard IEC motors. MCP3IMO pumps on bearing bracket can also be equipped with Nema frame motors.

- Connection for cleaning purposes

- Tapered shaft, fully machined

- High strength column support pipe. Rigidly maintains alignment between motor and casing. Protects pump shaft.

- By-pass for overflow

- Cantilever design = no mechanical seals, no plain bearings. Reduced downtime and operating costs. No bottom bearing, no oil or water pipes required to lubricate these bearings.

Application areas

Particularly suitable for pumping liquids that are difficult to seal such as hot frying oil up to 200° C.

They are also used for pumping waste water from industrial waste such as CIP, acids, condensate, etc.