CM

The CM is a hygienic colloid mill with toothed rotor and stator in electropolished duplex stainless steel. They are used to grind particles in suspension precisely and with reproducible results in an annular gap between the stator and rotor which can be adjusted by changing the axial position of the rotor. The rotor and stator contain 2 milling zones and thanks to the high shear forces between rotor and stator the CM will also mix the fluid.

-

Properties

Property Max. flow 15 m3/h Differential head 35 m wc Max. pressure Inlet: 10 bar Viscosity 100.000 cP with feed pump Max. temperature 140 °C Max. drive power 45 kW Speed 3600 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L and duplex Mechanical seal configuration Single, bellow, sterile, quench, double Available material O-ring EPDM, FKM, FEP-FKM, FFKM Connections Hygienic fittings Surface finish Hygienic quality, electropolished Certificates 1935/2004 EC. FDA. USP -

Description

The CM is a hygienic colloid mill with toothed rotor and stator in electropolished duplex stainless steel. They are used to grind particles in suspension precisely and with reproducible results in an annular gap between the stator and rotor which can be adjusted by changing the axial position of the rotor. The rotor and stator contain 2 milling zones and thanks to the high shear forces between rotor and stator the CM will also mix the fluid. -

Downloads

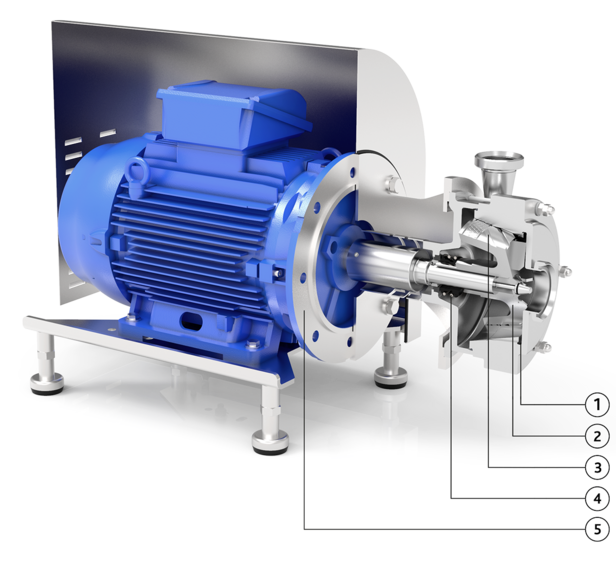

- Adjustable milling gap between rotor and stator

- Integrated centrifugal impeller

- Helicoidal rotor grooves

- Standardized mechanical seals to EN 12756

- Monobloc execution with std. IEC motors

Application areas

The Packo shear mixer pump is mainly used for in-line mixing, homogenisation and dispergation applications.

Mixing of two liquids:

With a large different specific gravity,

Having a large different viscosity or that are difficult to mix.

Also dispersing of:

Solids in liquids

Dispersion of gas in liquids.