Process

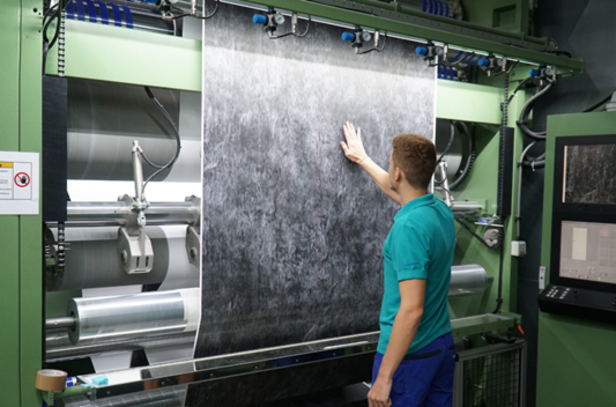

When aiming for high-volume printing, the primary focus is on achieving optimal print quality and ensuring proper machine maintenance to deliver the best possible end product.

The Verderflex Rollit peristaltic pump is manufactured from quality material and fitted with three PTFE rollers. The heart of the pump is fitted with a unique extruded hose element that represent a heavy-duty, high-volume hose pump that can operate with a lubrication free casing.

Problem

A major high-speed décor printing manufacturer conducted a 6-month test on various Rollit Peristaltic hose pumps. The objective of the test was to compare the Rollit peristaltic hose design to their previously used technology and equipment, which had issues with paint shear and pulsation frequency. Additionally, the manufacturer wanted to evaluate how well the Rollit pump protected the rheology of the paint during the transfer process.

Solution

The heart of the Rollit peristaltic pump, the internal part of the hose is the only portion of the pump in-contact with the paint. The “tube like” construction in combination with the 3 PTFE rollers induce very low to no pulsation. Consequently delivering a smooth flow of paint in a linear motion with no paint shear at any pump speed.

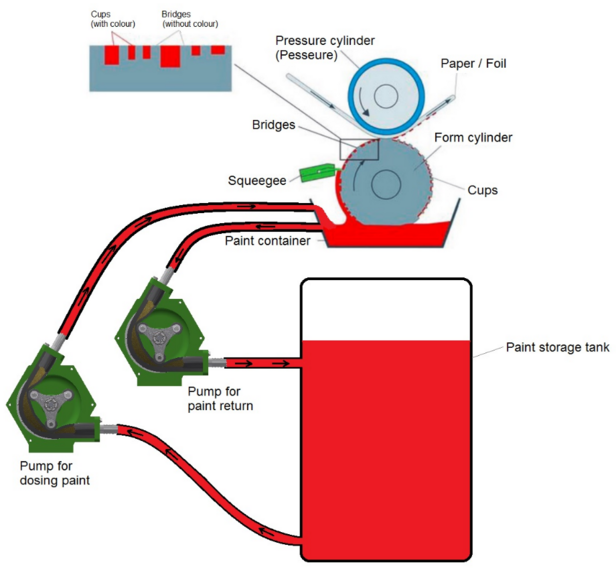

The test application

The purpose of the pump is to transfer the paint from a storage tank to the print roller. The print roller then applies the paint to the drum that is in turn pressed onto the “canvas” as an image. The process repeats itself with different colours until the final image is obtained. It is extremely important to maintain the paint rheology during the paint transfer, no shearing, foaming, bubbling or any characteristic change of the paint is allowed.

The Result

The printing manufacturer was pleasantly surprised with the Rollit’s design after the 6-month test. The customer reported that the Verderflex Rollit peristaltic technology was superior in maintaining the paint rheology than previously used and tested technologies. There were no paint defects, no foaming, bubbling, paint shear of increase in heat was detected at any flow over the test period.

The lubrication free pump had no risk to paint contamination during a hose paint colour change. Previous technology required the 2 pumps per colour to be removed from service, and 2 pumps installed to maintain production. The removed pumps contained paint that went to waste during the pump clean procedure. The Rollit pump design enables a quick in-situe hose replacement (in 2 minutes) with no paint wastage detected.

Why a Verderflex Rollit?

The Verderflex Rollit peristaltic hose pump-maintained paint rheology, no defects of paint wastage was detected. The quick hose change, dry running and self-priming ability of the peristaltic pump outperformed the customers current installed technology.

Curious about the price of a Verderflex peristaltic pump?

Our experts can help you with the right pump for your process!