FMS

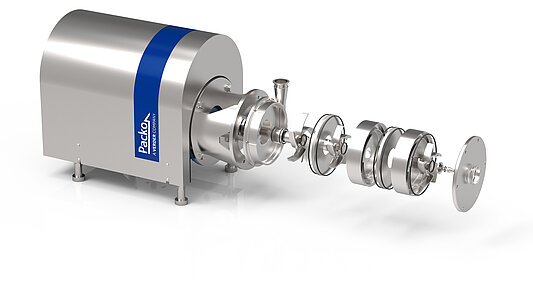

The hygienically executed Packo multistage pumps from the FMS series are used as process pump in the most diverse applications in food (milk, beer, soft drinks, ...), pharmaceutical and chemical industries and this for food, beverages, medicines, lotions, etc. Typical applications are found in filtration, pasteurization, filling machines, high pressure CIP systems, process pump for plate heat exchangers, etc.

-

Properties

Property Max. flow 220 GPM Max suction lift 705.2 feet Max. Inlet pressure 145 PSI Viscosity 250 cPs Max. temperature 284 °F Impeller type Open Max. free passage 0.55 inch Max. drive power 60.35 hp Speed 3000 / 3600 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L or similar Mechanical seal configuration Single, quench, double Available material O-ring EPDM, FKM Connections Hygienic fittings Surface finish Hygienic quality, internal welds hand polished + electropolished Certificates 1935/2004 EC. ATEX. FDA. EAC -

Description

The hygienically executed Packo multistage pumps from the FMS series are used as process pump in the most diverse applications in food (milk, beer, soft drinks, ...), pharmaceutical and chemical industries and this for food, beverages, medicines, lotions, etc. Typical applications are found in filtration, pasteurization, filling machines, high pressure CIP systems, process pump for plate heat exchangers, etc.

Pump series FMS

The hygienically designed Packo multistage pumps from the FMS series are used as process pump in the most diverse applications in food, pharmaceutical and chemical industries. They are the right match for operations at moderate flows and high pressures.

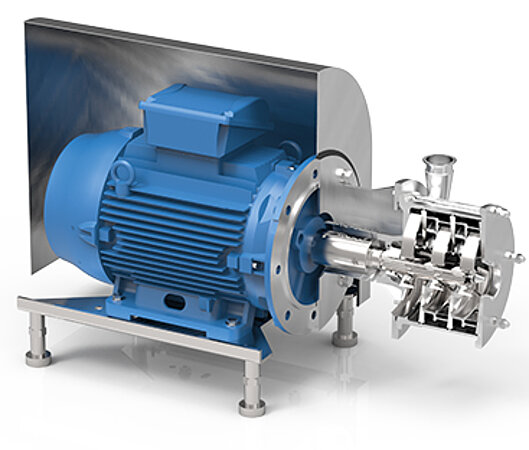

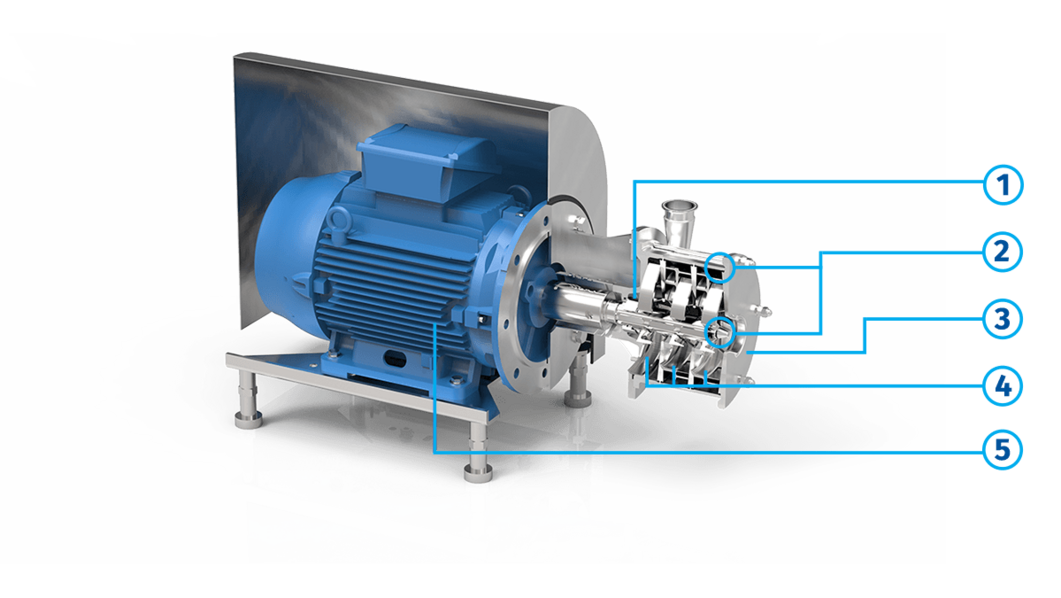

- Electropolished, easy to clean construction, no bacteria traps and no small clearances in order to clean the area around the O-ring

- Investment cast design

- Large seal cavity to clean mechanical seal properly

- Open impellers: no axial forces on motor bearings

- Monobloc execution with std. IEC motors

Application areas

For use in food, brew, beverage, pharmaceutical and chemical industries, as transfer and mixing pump for liquid food products, drinks, medicines, lotions, etc.

Typical applications: process pump for plate heat exchangers, pasteurizer systems, filters, filling machines, mixers, deaerators, carbonators and high pressure cleaning systems.

Your benefits

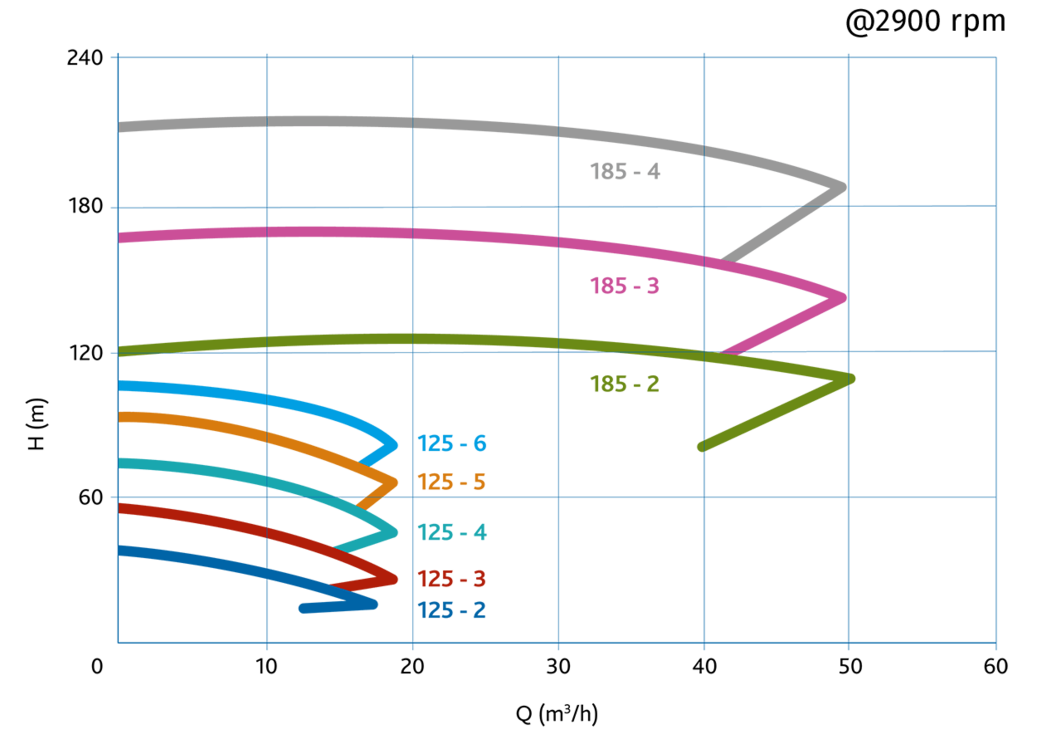

- Ideal for operation at moderate flow rate and high pressures

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: easy to clean

- Easy construction and easy maintenance: less downtime

- Standard components

- Easy to install

Assembly and disassembly videos

Assembly video - configuration with bellow seal

Assembly video - configuration with sterile seal

Assembly video - configuration with quench and bellow seal

Assembly video - configuration with double seal

Disassembly video - replacement of bellow seal

![[Translate to US English:] Replacement FP2-ICP2-PHP2-CRP2-MSP2-MFP2-SFP2-IRP2-IFF2-MFF2 sterile seal 20](/fileadmin/_processed_/5/1/csm_Replacement_FP2-ICP2-PHP2-CRP2-MSP2-MFP2-SFP2-IRP2-IFF2-MFF2_sterile_seal_20_fd59bf1793.png)