GFP

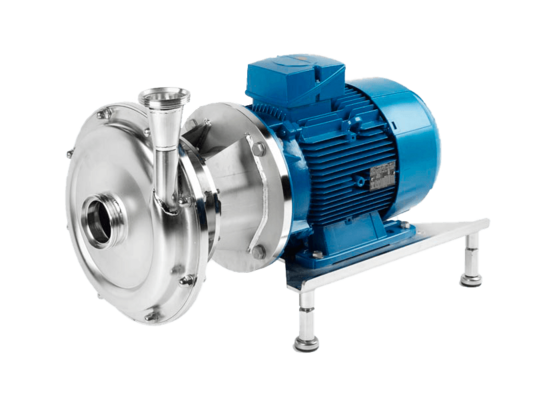

Večfazna črpalka je kombinacija standardne centrifugalne črpalke in črpalke s tekočim obročkom, ki sta nameščeni skupaj na 1 motor in 1 gred. Centrifugalna črpalka se uporablja za črpanje tekočine in prinaša glavno zmogljivost črpalke. Ko se plinski mehurček začne kopičiti v očesu centrifugalnega rotorja, ga evakuira tekoči obroč. Črpalka ima 1 sesalni in 2 izpusta: glavni izpust centrifugalne črpalke in manjši izpust črpalke s tekočim obročkom, ki deluje kot odzračevalnik za zrak in peno. Odzračevalnik za zrak / peno je običajno priključen nazaj na sesalno posodo.

-

Lastnosti

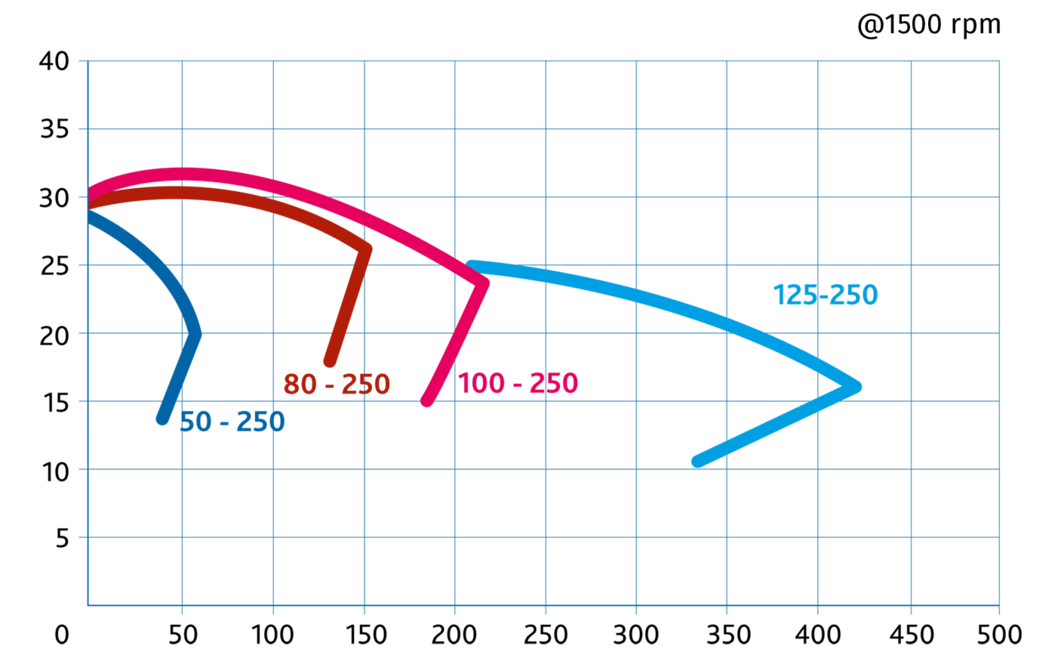

Črpalka Max. flow 400 m3/h Differential head 30 m wc Max. Inlet pressure 10 bar Viscosity 1000 cP Max. temperature 140 °C Tip rotor Open or closed Max. gas content 30% Max. drive power 45 kW Speed 1800 rpm Na voljo frekvenca 50 / 60 Hz Materials wetted parts Stainless steel 316L or similar Mechanical seal configuration Single bellow, sterile Available material O-ring EPDM, FKM, FFKM Connections EN1092-1 & ANSI flanges. DIN11851. SMS. RJT. Tri-Clamp Surface finish Electropolished Certificates FDA. EAC -

Opis

Večfazna črpalka je kombinacija standardne centrifugalne črpalke in črpalke s tekočim obročkom, ki sta nameščeni skupaj na 1 motor in 1 gred. Centrifugalna črpalka se uporablja za črpanje tekočine in prinaša glavno zmogljivost črpalke. Ko se plinski mehurček začne kopičiti v očesu centrifugalnega rotorja, ga evakuira tekoči obroč. Črpalka ima 1 sesalni in 2 izpusta: glavni izpust centrifugalne črpalke in manjši izpust črpalke s tekočim obročkom, ki deluje kot odzračevalnik za zrak in peno. Odzračevalnik za zrak / peno je običajno priključen nazaj na sesalno posodo.