GFP

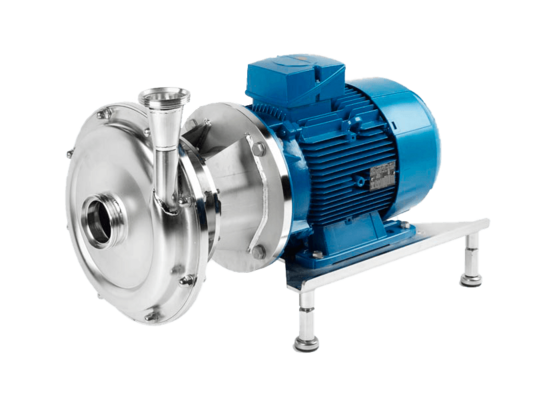

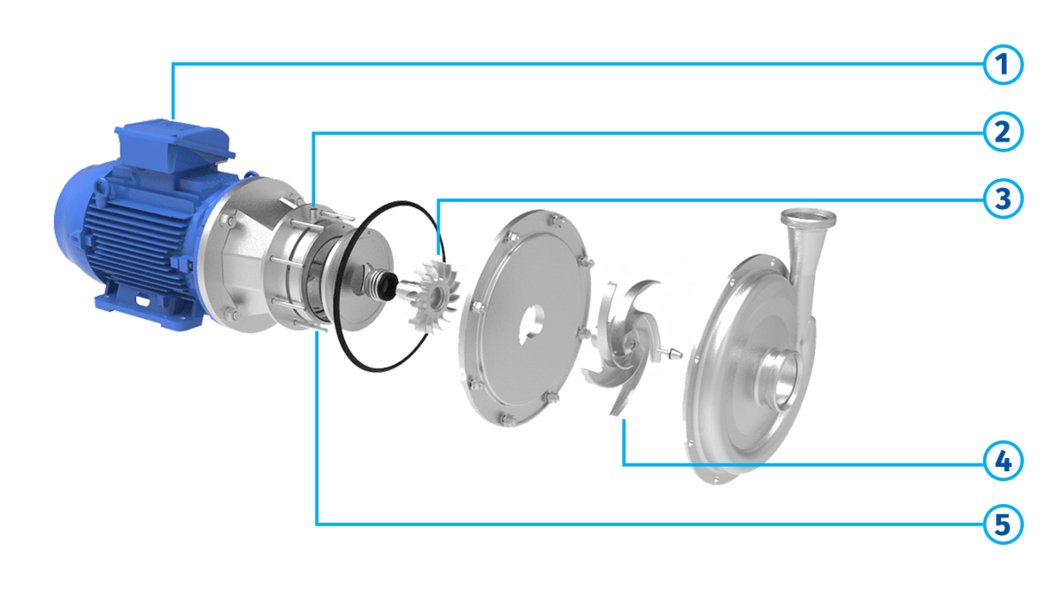

The multi-phase pump is a combination of a standard centrifugal pump and a liquid ring pump both mounted together on 1 motor and 1 shaft. The centrifugal pump is used for pumping the liquid and brings the main performance of the pump. When a gas-bubble starts to build up in the eye of the centrifugal impeller, it is evacuated by the liquid ring impeller. The pump has 1 suction and 2 discharges: a main discharge of the centrifugal pump and a smaller discharge of the liquid ring pump that functions as an air and foam vent. The air/foam vent is typically connected back to the suction vessel. The GFP multi-phase pump is typically used for foamig liquids and (viscous) liquids containing gas in the food-industry. Offering a solution to liquids that are difficult to pump with standard centrifugal pumps. E.g. starch slurries & proteins

-

Svojstva

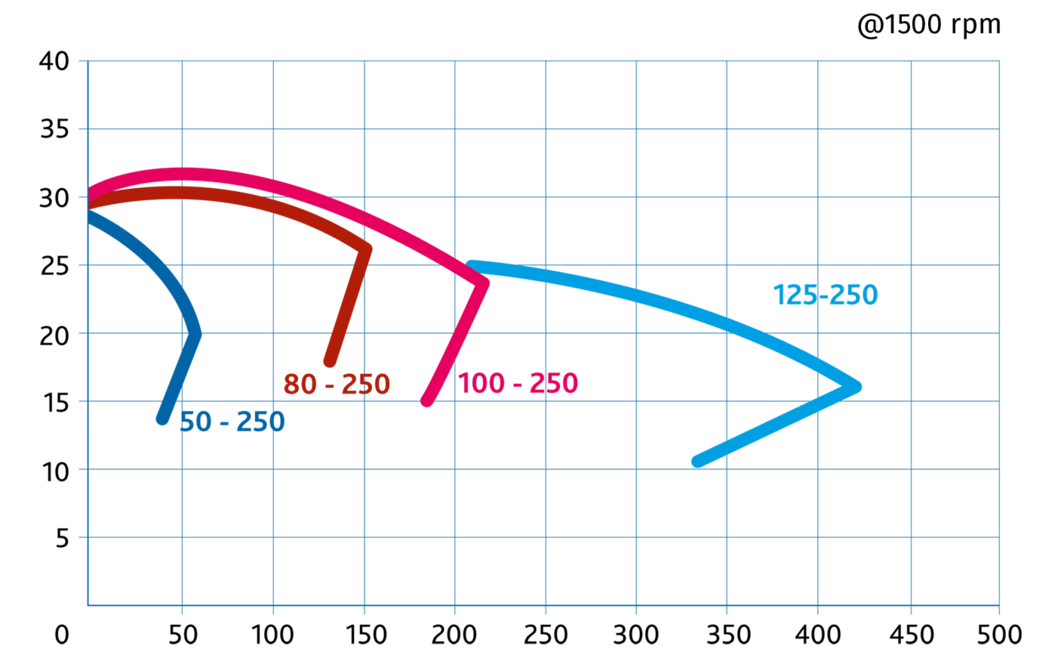

Tehničke karakteristike Max. protok 400 m3/h Visina dizanja 30 mVS Max. Inlet pressure 10 bar Viskozitet 1000 cP Max. temperatura 140 °C Tip radnog kola Open or closed Max. gas content 30% Max. pogonska snaga 45 kW Brzina obrtanja 1800 rpm Dostupna frekvencija 50 / 60 Hz Materials wetted parts Stainless steel 316L or similar Mechanical seal configuration Single bellow, sterile Available material O-ring EPDM, FKM, FFKM Priključci EN1092-1 & ANSI flanges. DIN11851. SMS. RJT. Tri-Clamp Surface finish Electropolished Sertifikati FDA. EAC -

Opis

The multi-phase pump is a combination of a standard centrifugal pump and a liquid ring pump both mounted together on 1 motor and 1 shaft. The centrifugal pump is used for pumping the liquid and brings the main performance of the pump. When a gas-bubble starts to build up in the eye of the centrifugal impeller, it is evacuated by the liquid ring impeller. The pump has 1 suction and 2 discharges: a main discharge of the centrifugal pump and a smaller discharge of the liquid ring pump that functions as an air and foam vent. The air/foam vent is typically connected back to the suction vessel. The GFP multi-phase pump is typically used for foamig liquids and (viscous) liquids containing gas in the food-industry. Offering a solution to liquids that are difficult to pump with standard centrifugal pumps. E.g. starch slurries & proteins

Pumpa serije GFP

Višefazna pumpa je kombinacija standardne centrifugalne pumpe i pumpe sa tečnim prstenom, obe montirane zajedno na 1 motor i 1 vratilo. Centrifugalna pumpa se koristi za pumpanje tečnosti i donosi glavne performanse pumpe.

Kada mehur gasa počne da se nakuplja u oku centrifugalnog radnog kola, on se evakuiše pomoću radnog kola sa tečnim prstenom.

Pumpa ima 1 usis i 2 pražnjenja: glavno pražnjenje centrifugalne pumpe i manje pražnjenje pumpe sa tečnim prstenom koja funkcioniše kao ventil za vazduh i penu. Ventilacioni otvor za vazduh/penu je obično povezan nazad sa usisnom posudom.