LT Series Truck Mounted Pumps

-

Properties

Property Bearing Housing Epoxy coated aluminium Elastomers Nitrile to 3A 18-02- EPDM to FDA title 21, para 177.2600- Viton to FDA title 21, para 177.2600- PTFE Body Materials 316 stainless steel (1.4401) Standards Conforms to US-3A standard 02-11, Designed to meet EHEDG protocols for CIP, US-FDA materials of construction Drive "Plug-in" Hydraulic motor mounting. Conventional long coupled drive for electric motor, hydraulic motor or PTO, using LH Series (not shown) Flow Rate - LT52 - 254 L/M- LT54 - 437 L/M- LT62 - 461 L/M- LT64 - 684 L/M (lpm) Cover Plain Integral pressure relief valve Port(s) Clamp, BSP, IDF, RJT, SMS, DIN, 3A bevel seat, NPT, others on request Max. Pressure - LT52 - 15 Bar- LT54 - 8 Bar- LT62 - 15 Bar- LT64 - 8 Bar (bar) Seal O-ring seals - Single mechanical seal - carbon/stainless steel - carbon/silicon carbide - silicon carbide/silicon carbide - all with flush if required Temperature -30 to +140 °C Viscosity 1 to 1 million cP -

Description

-

Downloads

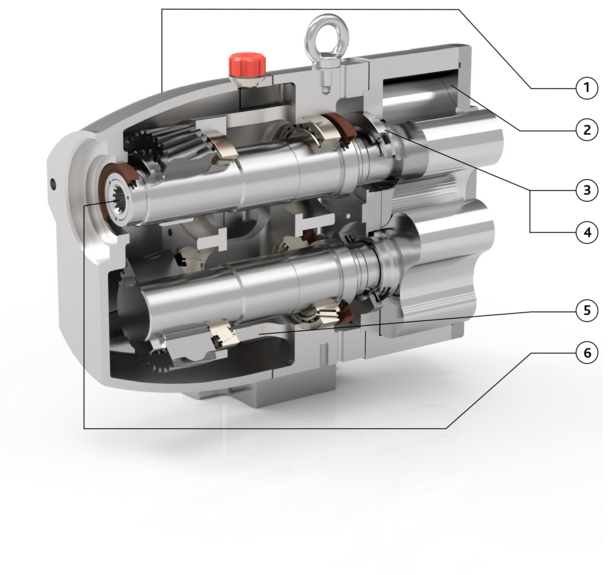

Pump series LT

The LT series are hygienic truck loading/unloading pumps. All product-wetted parts are made from 1.4404/316L stainless steel, to match highest hygienic standards. The use of compact, direct-coupled hydraulic motors enables space-saving and flexible installation.

- Epoxy coated lightweight aluminum gearbox and gearbox cover.

- Smaller clearances result in less slip which results in better efficiency when pumping low viscous fluids.

- Design and position of the seals, brings the CIP-fluid in direct contact with them.

- Wetted seal parts can be replaced without disassembling the rotor case: pump does not need to be mounted out of the installation to change seals.

- Food grade oil-filled gearbox increases bearing lifetime and requires minimal service effort.

- Hollow shaft design allows space saving direct coupled hydraulic motor installation.

Application areas

LT truck pumps are designed to handle low and high viscous products in bi-directional operation, they offer a very good efficiency especially with low viscosity products . A high displacement, good suction capability and good cleanability are further features of the LT series. With the direct coupled hydraulic motor the LT is best suited to be installed in small areas, or where no electric drive is possible.

Your benefits

-

Cleaner

- Certified to EC1935/2004, and 3A versions available

- Wetted surfaces with Ra < 0.8 μm

- Wetted parts in SS316L/ 1.4404 -

Improved CIP performance

- - Optimized design to eliminate dead-spaces, O-ring grooves without dead corners.

- Wetted parts of mech. seal directly in the product stream. - Faster maintenance

- Pump can stay in piping/truck during replacing seals thanks to front loaded seals.

- No need to open gearbox for adjusting axial clearances between rotors and casing.

- Rotor change without timing - Extended service intervals

• The oil-lubricated gearbox avoids frequent relubrication of the bearings with grease.

• This reduces maintenance and increases operational reliability. - Universal mounting

- Pumps can be mounted with both horizontal and vertical port connections.

- Direct coupled hydraulic motors allow an operation where no electrical drives are possible.

- Short mounting dimensions also for narrow space conditions. - Heating jackets for casing and front cover, pressure relieve valve and many more options available.

-

Shorter downtimes/higher flexibility