How do rotary gear pumps work?

An internal rotary gear pump is a positive displacement pump which employs a rotor and idler gear assembly to generate its flow. The assembly is offset, using a crescent adjacent to the inner gear, all within an outer gear.. As the rotor gear drives the idler gear, the space caused by the crescent offsetting the gears and the meshing of the gear teeth displace the fluid, expelling it to the discharge port.

What applications and fluids is it suitable for?

An internal rotary gear pump is typically specified for viscous fluids such as oils, bitumen, fats, syrups, chocolate and resins as the more viscous the product is, the more efficient the displacement aspect of the working principle becomes. An internal rotary gear pump can handle fluids with a viscosity of 100,000cSt!

Question about how rotary gear pumps work?

Do you need help? Our pump experts are there for all your questions!

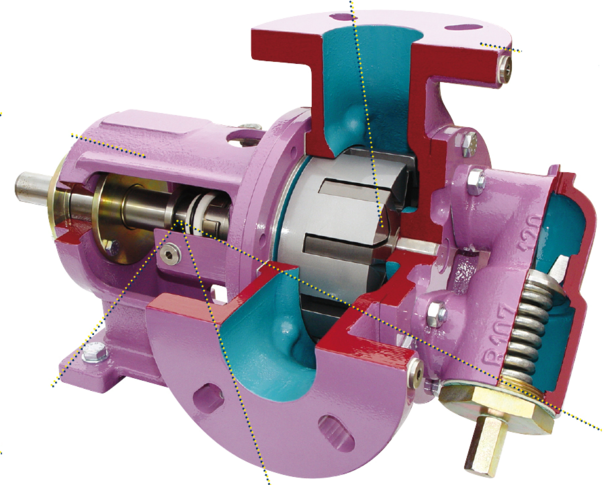

Internal rotary gear pump working principle

An internal rotary gear pump employs a positive displacement principle. The pump features a casing in which a dual gear (an outer rotor gear and an internal idler gear) and crescent assembly is housed. As the rotor gear begins to turn, the idler gear rotates with the teeth beginning to mesh accordingly. It is the space between these gears and the meshing action which both draws in the fluid and displaces it. The crescent shape both offsets the idler gear and provides a seal between the suction and discharge ports.

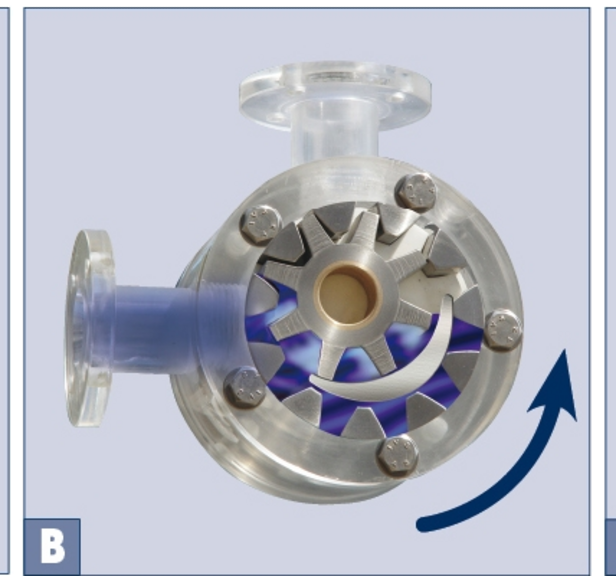

Fluid path and gear mechanism

On the picture on the right, you see the fluid path and gear mechanism. Two gears generate the flow - The rotor (1) and the idler (2). The rotor drives the internal idler. As the gears rotate, liquid is drawn into the spaces by the crescent (3) and smoothly transported towards the discharge port, where the gears mesh, closing the space and expelling the fluid. The result is a constant, smooth flow with no pulsation.

The advantages of an internal rotary gear pump - Smooth flow of viscous fluids

A gear pump has many advantages due to the gear mechanism being finished with close tolerances providing a highly efficient performance in terms of suction and discharge. The nature of the gear teeth and powerful motion makes it exceptional at handling viscous fluids up to 100,000cps including chocolate, fats, oils and similar.

Although the pump does handle solids and abrasive material well, the pump can handle shear sensitive fluids with a gentle non-pulsating flow thanks to the cumulative, smooth delivery of the gear teeth meshing. The flow is directly proportional to the speed, independent of the pressure, giving much greater control and reliability to the service operator.