Centrifugal Pumps

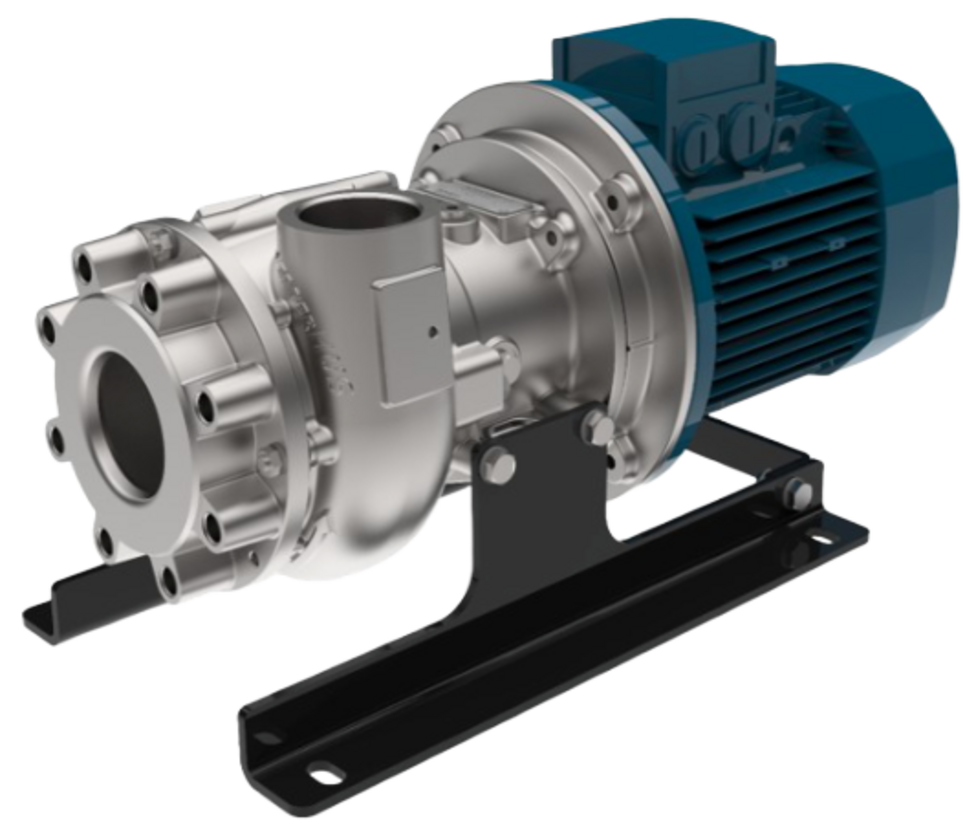

A conventional centrifugal pump provides a very efficient method of moving fluids in large volume, typically with a low viscosity and medium to small solids, though models are available for handling more difficult fluids. A centrifugal pump is a pump based on a rotodynamic principle. That makes this pump ideal for the transportation of polluted and abrasive liquids.

Working principle of a centrifugal pump

A centrifugal pump has a casing, with an impeller in the case: the component which transfers the energy from the motor drive into the fluid. Impellers are available in many configurations including shrouded, open and screw-type. The variation allows different fluids to be handled from water-thin, clean fluids through to handling larger solids such as potatoes or slurry suspensions such as liquid lime chemical.

Question about how centrifugal pumps work?

Do you need help? Our pump experts are there for all your questions!

Types of centrifugal pumps

There are many types of centrifugal pumps: screw centrifugal pumps, metallic and non metallic centrifugal magdrive pumps and industrial centrifugal pumps. There are also centrifugal pumps with a special high shear mixing method.

What kind of fluids can be handled by centrifugal pumps?

A lot of different fluids can be handled, and each fluid has unique charactistics which allows one pump do perform better then another pump. We always advise to contact our local offices, to talk about your specific fluid and which pump is suited the best.

Applications centrifugal pumps

Centrifugal pumps can be installed in a huge variety of applications. Typically, many of our customers choose Verdermag Global to handle aggressive fluids in high pressure systems where the pump is recirculating fluids remote locations due to the reliability of the pump.

Areas where leaks are simply not an option including ATEX rated zones, environmentally sensitive sites and where the workforce is in close proximity to the pump.