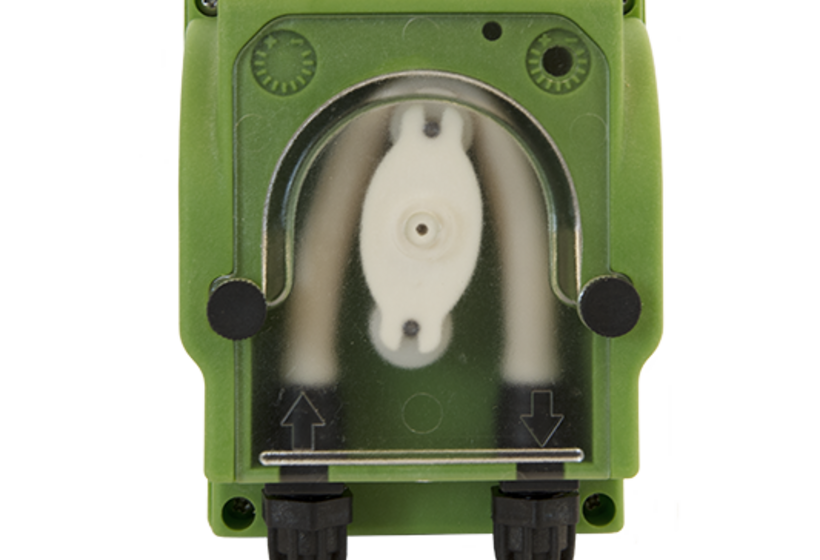

Pump solutions for your OEM projects

Day by day plant and mechanical engineers develop solutions to push our growth. They choose the right materials and components to master the challenges at the best. Plant and mechanical engineers are experts in their specialist field.

As an expert in pump solutions Verder offers a wide range of OEM pumps. We take individual care about your pump challenge to ensure your OEM solution is economical, perform to your expectations and we support you with any technical assistance you require. Verder is your partner for OEM pump solutions.

Looking for a pump solution?

If you need help deciding which pump is best for your application, please feel free to contact our pump experts.