Shear is the difference in speed between 2 layers in the liquid. The degree of the shear is expressed by the shear rate, which represents the velocity gradient in the liquid. When 2 layers of liquid that are 1m apart have a speed difference of 1 m/s, then there is a shear rate of 1/s in the liquid between these 2 layers.

As soon as a liquid is in motion, shear is created. The velocity is never the same for each liquid droplet, so there is always a relative movement of one droplet versus the other, thus creating shear. Even with so-called plug flow, shear will form on the wall because this wall is stationary or moves faster than the liquid and thus slows down or entrains the liquid.

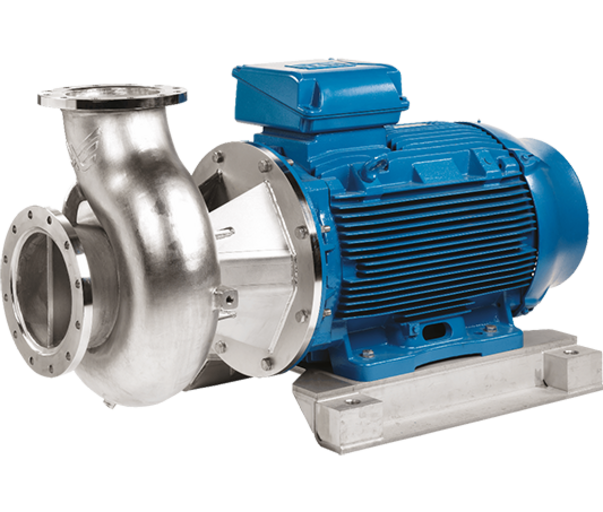

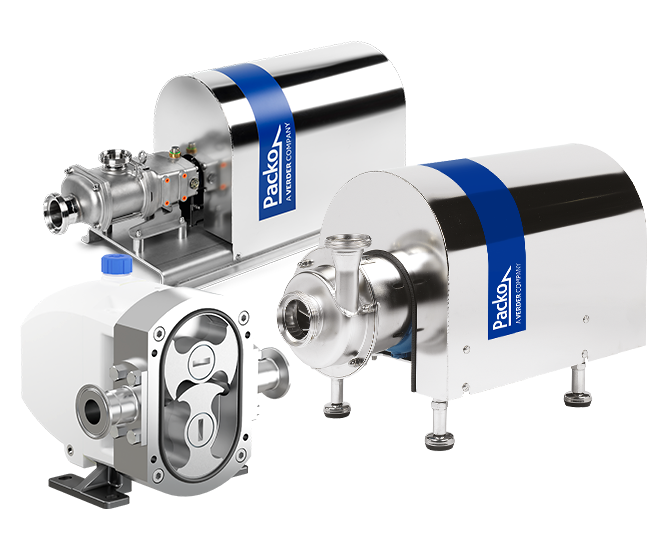

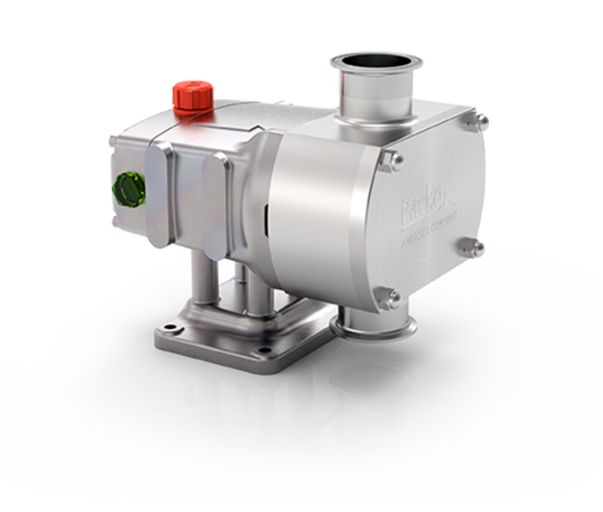

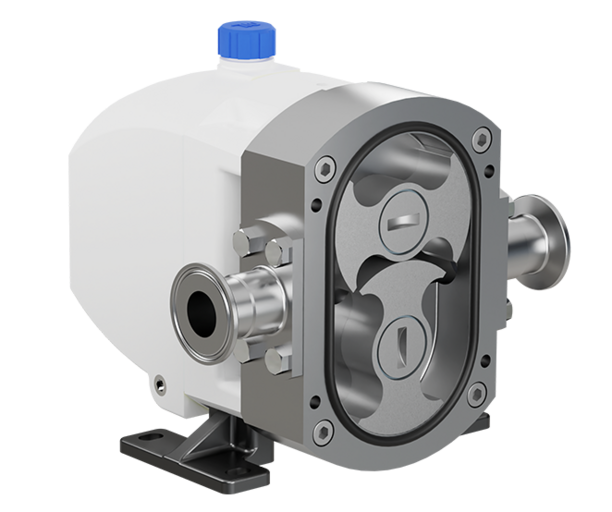

In pumps, there are moving parts as well as stationary housing. In view of the small distance between the moving parts and the housing, a large velocity gradient or high shear rate will develop in the fluid between them. The flow will also cause shear in the supply and discharge pipes, albeit a lower one.

Shear cannot be avoided and is not a problem in itself. Sometimes a high degree of shear is even desirable. For example, in a high-shear pump a high shear rate is generated to form emulsions or dispersions, or in general, to mix liquids that are difficult to dissolve into each other more or less stably.

However, the impact of shear on the microstructure of a fluid is not always positive or desirable. Shear, for example, can also damage sensitive liquids. Due to the shear stress between the liquid particles, an impact on the viscosity of the liquid is also seen in many complex liquids.

Liquids whose viscosity is not influenced by the shear rate are called Newtonian liquids. They are typically chemically simple liquids: water, oil, sugar solutions, ...

With much more complex liquids (preparations), the viscosity will decrease as the shear rate increases. These liquids are called thixotropic. As soon as the shear rate decreases, the viscosity increases again. The shear does not destroy the liquid structure and will not change it permanently. This means that a thixotropic liquid has the highest viscosity in a tank where it is at rest, so no shear. Due to the shear created by flow through a pipe, the viscosity decreases. In a pump, where the shear rate is much higher, the viscosity is at its lowest. When the liquid leaves the pump, the viscosity recovers as the shear rate falls back.

With a small group of liquids, the viscosity actually increases with a higher shear rate. These liquids are called dilutant. Examples of dilatant liquids are honey and concentrated starch solutions. Due to their dilatant behaviour these liquids are very difficult to pump.

The influence of the shear rate on the viscosity of these three types of liquids is shown graphically here: